Low-Temperature Coatings: The Energy-Saving Solution

Reduced Energy Costs, Shorter Throughput Times.

Energy costs are exploding, concern about the environment is growing. These factors make energy-efficient powder coatings increasingly important. IGP low-temperature powder coatings meet challenging requirements for sustainable, durable coatings. They stand out thanks to convenient curing windows from 130°C and guarantee optimum coating results.

IGP low-temperature powder coatings cut your energy costs for curing and simultaneously reduce throughput times in production. In our range you’ll find the ideal powder coatings for interior and exterior applications. They meet high standards in terms of aesthetic appeal and function, and can also withstand regular cleaning with no loss of quality.

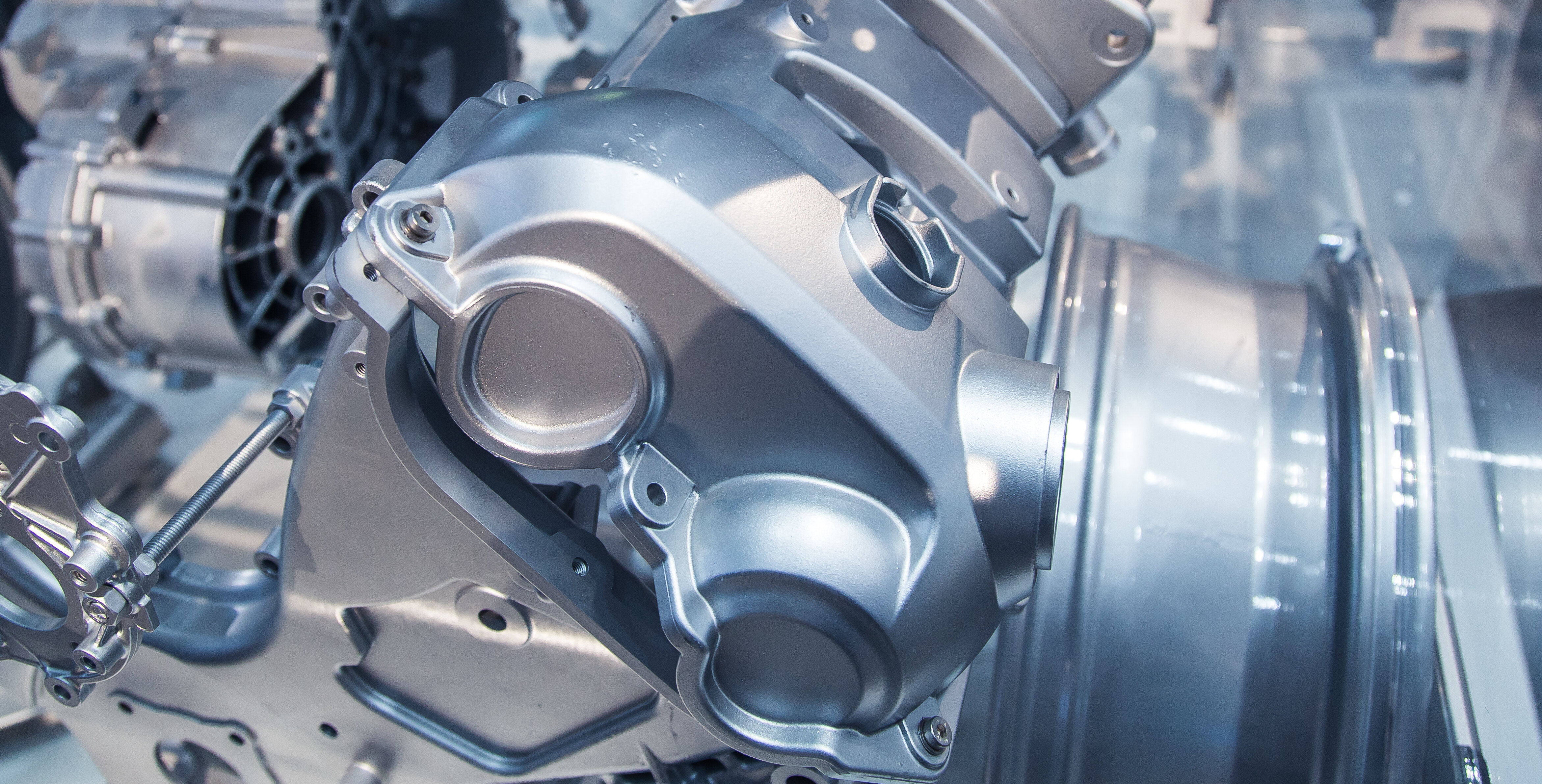

- Exterior Applications in Industry

For the efficient coating of solid components, attachments, and body parts for trucks, cranes, machines, agricultural vehicles, and wind turbine segments, IGP Pulvertechnik has developed highly reactive coating powder coatings for exterior surfaces. They are better for the environment, save energy, and reduce manufacturing times because they can be cured at temperatures as low as 150 °C. Therefore they are among the most cost-effective and sustainable types of coating. As a manufacturer, you benefit from significantly lower energy costs and faster throughput times in your production process.

- Heat-Sensitive Substrates

Powder coatings are commonly applied to metal components as one of the best ways to protect objects by means of tough yet highly attractive surfaces.

For decades, IGP has been working intensively on further developing powder coating technology. We have also been instrumental in creating powder coating solutions for heat-sensitive substrates such as solid wood, composites, and MDF. The powder coatings we have specifically developed for this area are durable, sustainable alternatives to wet paints.

- A Powder Coating System for all Needs – IGP-DURA®one 56

IGP-DURA®one 56 is the first quality-certified, highly reactive product series that lets you reduce object temperatures or accelerate throughput times in the curing oven. Its excellent over-curing stability ensures process reliability. With IGP-DURA®one 56, you can optimize your entire coating process cost-effectively and sustainably.

IGP Powder Coatings launches IGP-DURA®one 56, the first quality-certified high-reactive product range. The range enables object temperatures to be reduced or process speeds to be increased. Energy savings can be realized economically and sustainably in this way. The high overburning stability of the powder coatings also ensures process reliability. The use of IGP-DURA®one 56 simplifies production planning, especially for coating companies with several powder suppliers. That's why it's "Keep cool, take one!" - one powder coating system for all requirements.