VR208 - Weather-Resistant, Industrial Quality

Transparent, Glossy Powder Coating System for Graffiti Protection on Metal Surfaces

Product Description

The system 8909B was developed as a top coat powder coating for permanent protection against graffiti on metal surfaces.

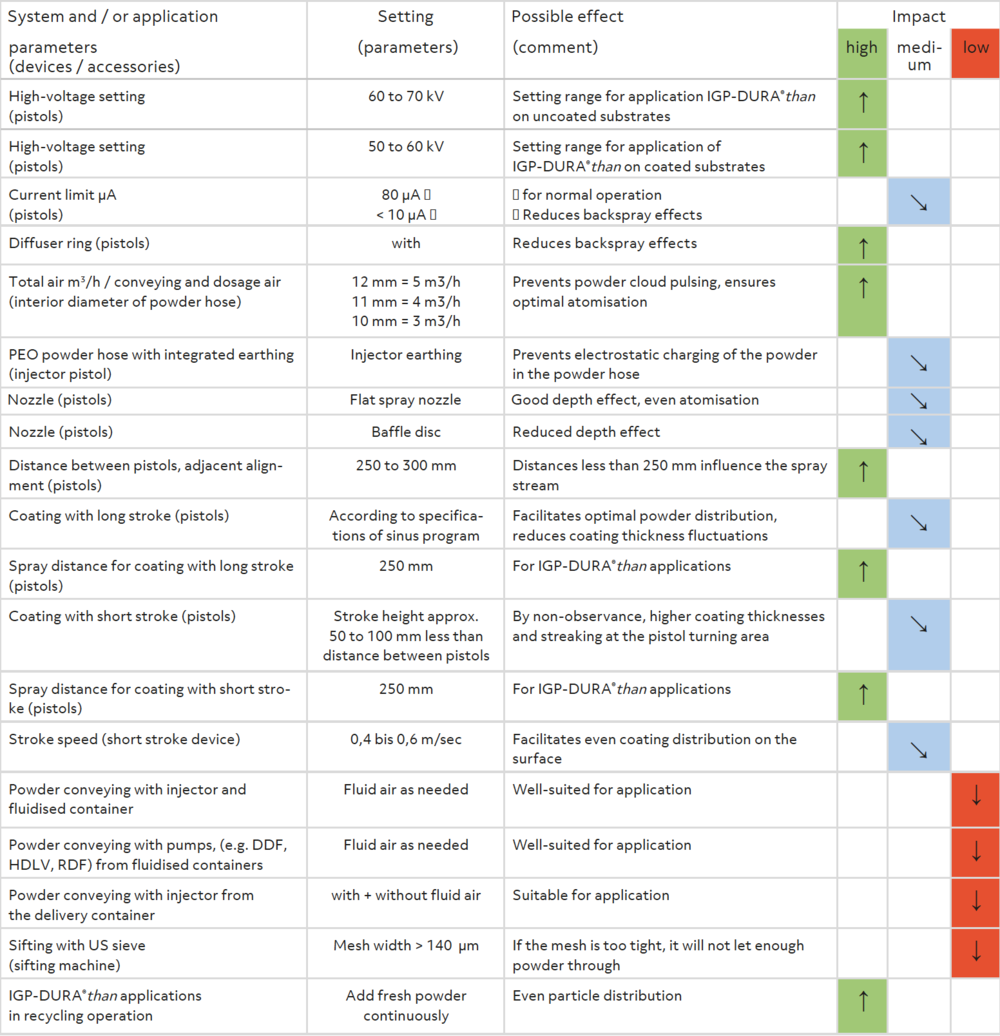

Application with Corona Pistols

The first coat is applied with a high-voltage setting between 60 to 70 kV. The second coat with 8909B is set between 50 to 60 kV. Back spray effects can be avoided by using diffuser rings (low ionic charge). We recommend flat spray nozzles. The spraying distance can be set to 250 mm. To optimize the coating thickness distribution for coating in long stroke operation, the speed of the lifting devices should be adjusted to the transport speed (coordinated sine wave pattern of pistols). For coating in short stroke operation, the stroke height must be adjusted to the distance between the pistols (coordinated pistol turning points). If using partially automated operation, any hand application required should be done as a pre-coating.

We recommend applying coating thicknesses of 50 μm to 70 μm. When using IGP-DURA®than 8909B for coating thicknesses > 90 μm, small bubbles may appear in the powder-coated surface after curing. We do not recommend the use of tribo coating pistols.

Recycling

When using IGP-DURA®than 8909B in recycling mode, we recommend the continuous addition of fresh powder. Maintenance and cleaning of all the system components (pistols, hoses, syclone, etc.) must be done with the utmost care.

Earthing

If using IGP-DURA®than 8909B, particularly on previously coated substrates, adequate earthing of the suspension racks must be ensured.

Curing Conditions

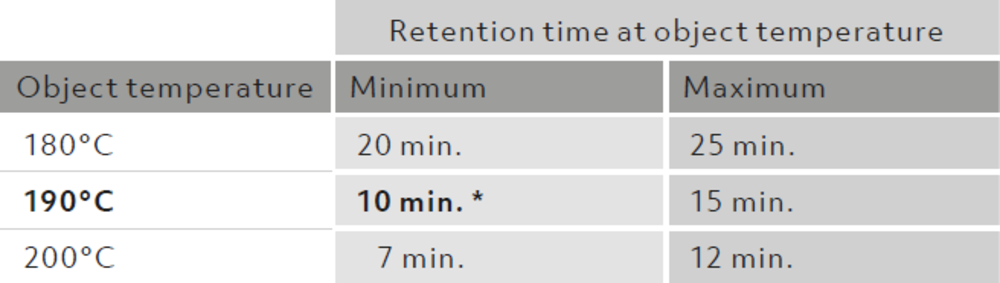

Time and temperature combinations that result in an ideal cross-linking of the coat are displayed.

* recommended curing conditions

If the object temperature remains below the required level, cracking in the powdered surface may occur. Exceeding the level will usually cause yellowing and foaming in the powder coating.

Based on these circumstances, we recommend before beginning production creating a temperature profile of the curing oven with an oven temperature measurement device using production conditions.

In any case, taking the recommended curing conditions into consideration, the curing of the coated object should be based on the combination of retention time and object temperature determined by the oven temperature measurement device. The recommended temperature and time combination may not be exceeded under any circumstances.

Ventilation and Smoke Production

When using 8909B, elimination products escape in the form of caprolactam. Elimination products generate a lot of smoke, which must be removed from the oven interior by adequate ventilation in the curing oven. If the curing oven is not equipped with an adequate ventilation system, then it is absolutely imperative to ensure that the room and oven have adequate ventilation. When doing so, it is important to observe the list of notices about particular risks (R statements Xn R20/R22 and R statements Xi R36/37/38). Deposits of elimination products in the curing oven, in particular the oven walls and in the ventilation system, must be removed in due course depending on intensity.

Stripping

IGP-DURA®than 8909B is difficult to strip using chemicals. Multi-component hangers used during the coating process can be freed of residual powder coating by means of flame stripping.

Applicable Documents

- Safety information sheet SD 120

- Technical data sheet IGP-DURA®than 8909B

Further recommendations for IGP-DURA®than 8909B applications

These application-related recommendations are based on current knowledge, but are to be regarded as non-binding information and do not release you from your obligation to conduct your own tests.