TI000 - Categorization of Effect Powder Coatings

The various effect powder coatings have different requirements regarding processing. To aid fault-free processing, the different processing conditions for IGP-Pulvertechnik effect powder coatings are divided into five categories (1–5 stars).

You can find information on the process requirements as well as processing tips according to the categorization of each article. You can find further details about coating parameters as well as information on recycling in the relevant processing instruction. The category of your powder coating as well as the corresponding processing instruction are printed on the label of the box or big bag.

General Information

The parameters and recycling rates recommended in the IGP processing instructions are guideline values. For each individual order, the coating company must check these on its own plants and adjust them if necessary.

As the coating plant type and the configured parameters have a significant impact on the effect shade achieved, we urgently recommend performing a suitability test with the plant before the start of processing.

To ensure a consistent ratio and composition of effect mixtures, it is advisable to start the coating process with a mixture of fresh and recycled powder.

This ratio should be maintained during the entire coating process.

Do not exceed the maximum recycled portion defined in the applicable processing instruction.

The coating company is responsible for regular inspection of the coated goods to ensure compliance with the released shade.

Note

The darker an effect powder, the higher the effect-agent content, and the finer the effect agent, the more challenging the processing.

IGP Effect Categories

5-STAR*****

- Effect agents are bonded with the powder grain to a large extent (IGP-Effectives® technology)

- 90% recyclability of the overspray

- Can easily be applied to all geometrical forms

- Manual and automatic coating possible without extra effort

4-STAR****

- Effect agents are bonded to the powder grain using the Premium Bond method

- As a rule, a recycled portion of max. 30% (according to the PI) is possible

- Powder coatings with slight fluctuations in the effect-agent content and deviating effect alignment can be applied largely homogenously to all geometrical shapes

- Manual and automatic coating possible

3-STAR***

- Small differences in the average effect agent content are visible to a slight extent

- Changes to the alignment of the effect pigments are visible

- to a slight extent

- Recycling is possible to a limited extent (according to the PI)

- We recommend producing limiting samples to determine the recycled portion

- We recommend producing a pilot series if a coating order will be carried out on different systems

- Avoid manual coating if possible.

2-STAR**

- Small differences in the effect-agent content can lead to a different color impression.

- Changes in the effect particle alignment can lead to a different color impression.

- Recycling is possible to a limited extent (according to the PI). It is essential to produce limiting samples in order to determine the recycled portion.

- If a coating order will be processed on different systems, it is essential to produce a pilot series.

- Manual coating is not recommended

1-STAR*

- Small differences in the effect agent content lead to a different color impression.

- Changes in the alignment of the effect particles lead to a different color impression.

- Recycling is only possible in individual cases. It is essential to produce limiting samples in order to determine the portion of recycled material.

- Avoid using different plants for one order.

- Only automatic coating

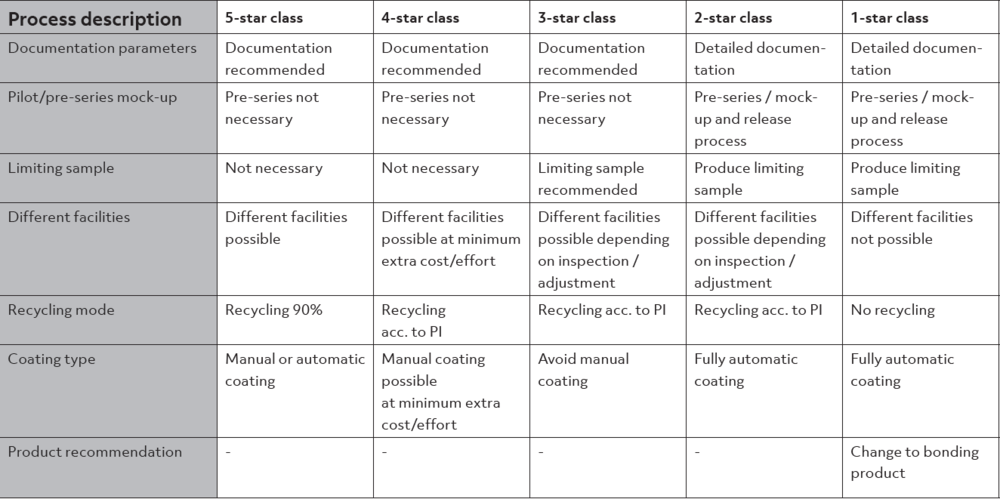

Overview of the IGP Effect Categories and Process Descriptions

The various effect powder coatings have different requirements regarding processing. To aid fault-free processing, the different processing conditions for IGP-Pulvertechnik effect powder coatings are divided into five categories (1–5 stars).